Process control equipment is often sold with the support of Sales Engineers working at the local or regional level. Realizing what these specialists have to contribute when specifying, purchasing and installing process control equipment, and taking advantage of their knowledge and talent, will save you time, keep budgets in line, and deliver a better project outcome . Here's how:

Experience:

Whether you're a project engineer, maintenance manager, specifying engineer, or purchasing agent, you may be working with a piece of process equipment of which you have little first-hand experience. Past exposure or training may provide an overall understanding, but you're missing the detail. It's impossible for one person to know it all. Safety, cost, and quality are tied to questions ranging from optimal valve selection for a given application, to proper heat exchanger sizing, to the limitations of certain kinds of pressure transmitters. For this reason, it's important to remember one of your best assets - the Technical Sales Rep.

Product Knowledge:

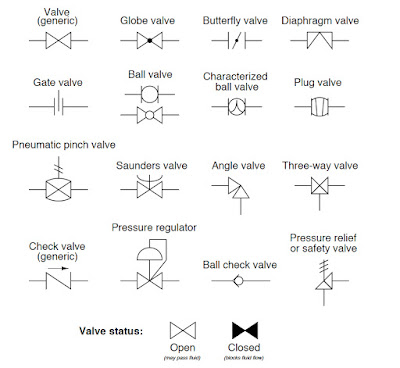

Specialized Sales Engineers, by the nature of their job, have product knowledge that is both broad and deep. They've applied every type of valve, actuator, instrument, and pneumatic device known. They've dealt with many other process plants who have similar needs.They are also current on new products, their capabilities and their proper application. Unlike information available on the Web, Sales Engineers can get advanced notice of product obsolescence and replacement options, new technologies coming to the market, and more. Also, because they are exposed to so many different types of applications and situations, sales engineers are a wealth of tacit knowledge that they readily share with their customers.

Access:

Through a technical Sales Engineer, you may be able to look “behind the scenes” with a particular manufacturer and garner important information not publicly available. Sales reps deal with people, making connections between customers and manufacturer's support personnel that may not normally be public facing. They make it their business to know what’s going on with products, companies, and industries.

Of course, Sales Engineers will be biased. Any solutions proposed are likely to be based upon the products sold by the representative. But the best sales people will share the virtues of their products openly and honestly, and tell you when they do not have the right product for your application. This is where the discussion, consideration and evaluation of several solutions becomes part of achieving the best project outcome.

As a stakeholder in your process operations, it's highly recommended you develop a professional, mutually beneficial relationship with a

process equipment specialist. Look at a relationship with the

local Sales Engineer as symbiotic.

Their success, and your success, go hand-in-hand.